tool tracking, hazardous materials, precision weighing Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com

Environmental pollution and the depletion of fossil fuels are two major challenges threatening human survival and global security. To address these issues, individuals and communities are increasingly adopting eco-friendly practices to prevent an energy crisis. Green technology is now at the forefront of innovation, aligning with the need for sustainable development.

Waste cooking oil is not only a serious environmental hazard but also a costly problem. In the UK, it costs up to £15 million (around RMB 140 million) annually to clear blocked sewers caused by this waste. However, innovative solutions are emerging to turn this problem into an opportunity.

In Kirklees, UK, residents have embraced a groundbreaking approach by converting used cooking oil into electricity. This initiative is a prime example of green living that helps tackle the energy crisis. A local recycling center collects large quantities of waste oil—both used and unused—and processes it to generate power for homes and offices. This method significantly cuts down carbon dioxide emissions compared to traditional energy sources and eases the financial pressure on taxpayers.

By utilizing waste oil for energy, the community supports long-term sustainability while playing a vital role in combating climate change. It’s a win-win solution that promotes environmental responsibility and economic efficiency.

Moreover, one liter of cooking oil can power a plasma TV for 50 hours, an energy-saving bulb for 225 hours, or a DVD player for 440 hours. These impressive numbers highlight the potential of using edible oil as a renewable energy source. It's not only cost-effective but also environmentally friendly and sustainable, offering new possibilities for technological advancement and green innovation.

This practice demonstrates how small, everyday actions can lead to significant positive impacts on both the environment and society.

Enclosure: Weighing cabinets create a contained environment around the weighing balance, preventing hazardous materials from escaping into the laboratory.

Ventilation: Most weighing cabinets are equipped with ventilation systems that draw air into the cabinet, filter it, and exhaust it to the outside or recirculate it within the cabinet. This helps to maintain a safe and clean working environment.

Safety glass: The front panel of a weighing cabinet is typically made of safety glass to provide visibility while protecting the operator from potential hazards.

Ergonomic design: Weighing cabinets are designed to be comfortable and easy to use, with features such as adjustable height and tilt.

Built-in features: Some weighing cabinets may have additional features, such as built-in lighting, power outlets, and storage compartments.

Benefits:

Safety: Weighing cabinets protect the operator and the laboratory environment from exposure to hazardous materials.

Accuracy: The controlled environment within a weighing cabinet can help to ensure accurate and precise weighing results.

Compliance: Weighing cabinets are often required to comply with safety regulations and standards in industries such as pharmaceuticals, chemicals, and research.

Efficiency: By providing a dedicated space for weighing operations, weighing cabinets can improve efficiency and productivity in the laboratory.

Applications:

Pharmaceutical industry: Weighing cabinets are essential for handling and measuring pharmaceutical ingredients, ensuring product quality and safety.

Chemical laboratories: These cabinets are used for weighing chemicals and other hazardous substances in research and development settings.

Research laboratories: Weighing cabinets are valuable tools for scientists conducting various experiments and analyses.

Quality control: In industries where precision weighing is critical, such as food and beverage manufacturing, weighing cabinets are used for quality control purposes.

Types of Weighing Cabinets:

Standard weighing cabinets: These are general-purpose cabinets suitable for a wide range of applications.

Powder weighing cabinets: Designed specifically for handling powders, these cabinets often have specialized ventilation systems to prevent the spread of airborne particles.

Hazardous substance weighing cabinets: These cabinets are equipped with advanced safety features to protect operators from exposure to highly toxic or hazardous substances.

Factors to Consider When Choosing a Weighing Cabinet:

Safety requirements: Consider the specific hazards associated with the materials you will be handling and choose a cabinet that meets the appropriate safety standards.

Ventilation system: Evaluate the ventilation system to ensure it is adequate for your needs and complies with relevant regulations.

Size and capacity: Select a cabinet that is large enough to accommodate your weighing equipment and the materials you will be handling.

Ergonomics: Ensure that the cabinet's design is comfortable and ergonomic for the operator.

Additional features: Consider any additional features that may be beneficial, such as built-in lighting or power outlets.

By investing in a high-quality weighing cabinet, you can create a safe and controlled environment for your precision weighing operations, ensuring accurate results and protecting the health and safety of laboratory personnel.

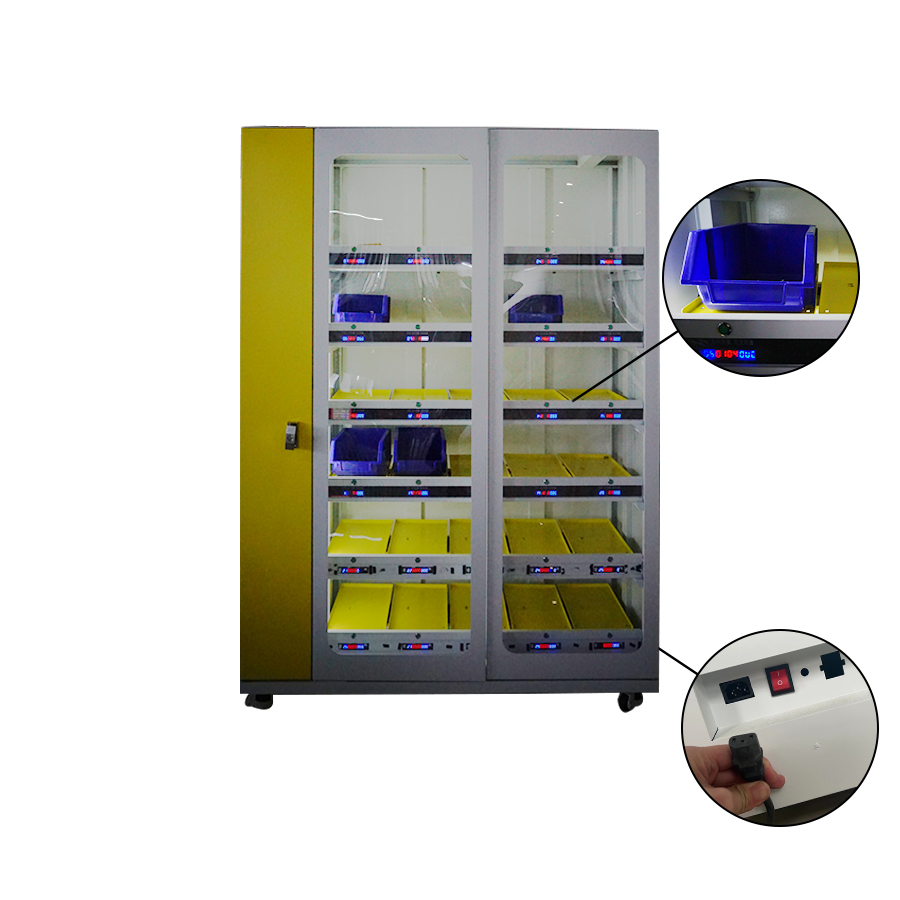

Product color: White yellow (customizable)

Capacity: 30 scales

Freight lane type: 6 floors * 5 lanes

Weighing sensor: A single weighing position can weigh up to 20 kg, a small weighing capacity of 5g, and an error of 1gram

Applicable system: optional card swiping, facial recognition, and fingerprint recognition

Power supply: AC220V/50HZ