Bamboo and wood flooring not only bring warmth in winter and coolness in summer, but also enhance the aesthetics of your living room while reflecting the personality of the homeowner. With the growing popularity of bamboo flooring in the market, the number of brands has increased rapidly, but product quality varies widely. So, what should consumers be aware of when choosing bamboo flooring? 1. What are the advantages of bamboo flooring? Bamboo flooring is crafted from high-quality natural bamboo, offering a beautiful texture that brings warmth, durability, moisture resistance, and an elegant look. It has better thermal conductivity and stability compared to wood flooring, making it ideal for underfloor heating systems. Additionally, it offers flexibility, noise reduction, and easy maintenance—similar to traditional wooden floors. 2. How is bamboo flooring different from wood flooring? Compared to wood, bamboo flooring typically lasts longer. High-end bamboo flooring often costs the same as mid-range wooden flooring. Both materials are sensitive to moisture, but bamboo has a higher fiber density. When submerged in water for 24 hours, bamboo expands less than half the amount of wood, making it more stable and less prone to warping. 3. Are there quality standards for bamboo flooring? High-quality bamboo flooring is made from mature bamboo (at least four years old), processed with high-temperature cooking, and finished with environmentally friendly adhesives and UV flame-retardant coatings. Always check for certifications. According to the national forestry standard LY/T1573-2000, key performance indicators include moisture content (6–14%), hardness (55.0 MPa), static bending strength (90 MPa for thickness over 15 mm), wear resistance (0.08 g/100 rpm), and formaldehyde emission (1.5 mg/L). Standard sizes include 900 × 90 × 18 mm, 900 × 110 × 18 mm, and newer options like 1820 × 150 × 18 mm. Checking these specifications can help ensure you're buying a quality product. 4. Is paint applied to bamboo flooring? Painting is essential during the manufacturing process. To protect the bamboo from moisture and enhance its durability, surface treatments such as UV coatings are used. Most products come with five sides painted on both sides, forming a protective layer. The paint should not be too hard; instead, it should have a balance of hardness and flexibility to provide good scratch and wear resistance. 5. Is bamboo flooring eco-friendly? Bamboo is one of the most sustainable flooring options available. As a fast-growing plant, it regenerates quickly without harming the environment. Bamboo absorbs and decomposes carbon dioxide up to 20 times more efficiently than regular trees, helping to improve indoor air quality. Moreover, its production involves no harmful chemicals, making it a safe and green choice for your home. 6. Does older bamboo make better flooring? The age of the bamboo doesn't necessarily determine the quality of the flooring. Manufacturers process bamboo to meet various consumer needs before it leaves the factory. Typically, bamboo used for home decoration is around 4–6 years old. Younger bamboo is too soft, while bamboo over 9 years old becomes brittle. Some sellers may highlight floor thickness as a selling point, but thicker flooring can actually indicate poor quality. In general, a thickness of 1.5 cm is ideal for most residential applications. tool tracking, hazardous materials, precision weighing Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com

Enclosure: Weighing cabinets create a contained environment around the weighing balance, preventing hazardous materials from escaping into the laboratory.

Ventilation: Most weighing cabinets are equipped with ventilation systems that draw air into the cabinet, filter it, and exhaust it to the outside or recirculate it within the cabinet. This helps to maintain a safe and clean working environment.

Safety glass: The front panel of a weighing cabinet is typically made of safety glass to provide visibility while protecting the operator from potential hazards.

Ergonomic design: Weighing cabinets are designed to be comfortable and easy to use, with features such as adjustable height and tilt.

Built-in features: Some weighing cabinets may have additional features, such as built-in lighting, power outlets, and storage compartments.

Benefits:

Safety: Weighing cabinets protect the operator and the laboratory environment from exposure to hazardous materials.

Accuracy: The controlled environment within a weighing cabinet can help to ensure accurate and precise weighing results.

Compliance: Weighing cabinets are often required to comply with safety regulations and standards in industries such as pharmaceuticals, chemicals, and research.

Efficiency: By providing a dedicated space for weighing operations, weighing cabinets can improve efficiency and productivity in the laboratory.

Applications:

Pharmaceutical industry: Weighing cabinets are essential for handling and measuring pharmaceutical ingredients, ensuring product quality and safety.

Chemical laboratories: These cabinets are used for weighing chemicals and other hazardous substances in research and development settings.

Research laboratories: Weighing cabinets are valuable tools for scientists conducting various experiments and analyses.

Quality control: In industries where precision weighing is critical, such as food and beverage manufacturing, weighing cabinets are used for quality control purposes.

Types of Weighing Cabinets:

Standard weighing cabinets: These are general-purpose cabinets suitable for a wide range of applications.

Powder weighing cabinets: Designed specifically for handling powders, these cabinets often have specialized ventilation systems to prevent the spread of airborne particles.

Hazardous substance weighing cabinets: These cabinets are equipped with advanced safety features to protect operators from exposure to highly toxic or hazardous substances.

Factors to Consider When Choosing a Weighing Cabinet:

Safety requirements: Consider the specific hazards associated with the materials you will be handling and choose a cabinet that meets the appropriate safety standards.

Ventilation system: Evaluate the ventilation system to ensure it is adequate for your needs and complies with relevant regulations.

Size and capacity: Select a cabinet that is large enough to accommodate your weighing equipment and the materials you will be handling.

Ergonomics: Ensure that the cabinet's design is comfortable and ergonomic for the operator.

Additional features: Consider any additional features that may be beneficial, such as built-in lighting or power outlets.

By investing in a high-quality weighing cabinet, you can create a safe and controlled environment for your precision weighing operations, ensuring accurate results and protecting the health and safety of laboratory personnel.

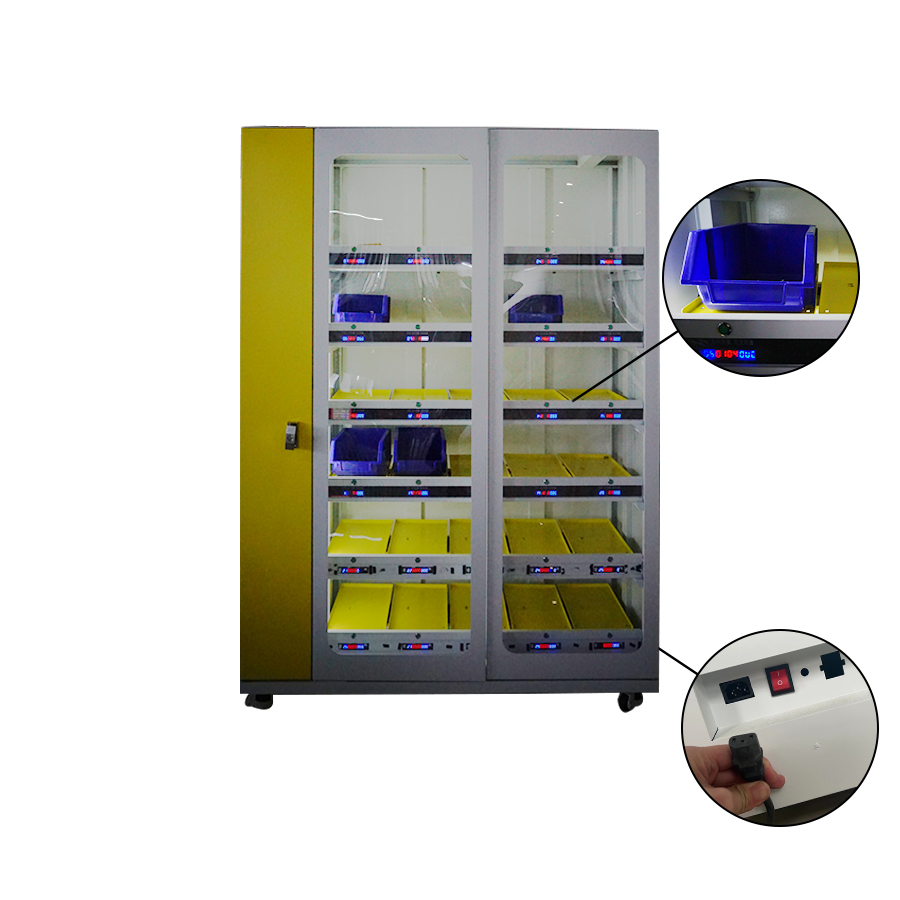

Product color: White yellow (customizable)

Capacity: 30 scales

Freight lane type: 6 floors * 5 lanes

Weighing sensor: A single weighing position can weigh up to 20 kg, a small weighing capacity of 5g, and an error of 1gram

Applicable system: optional card swiping, facial recognition, and fingerprint recognition

Power supply: AC220V/50HZ